It is indisputable that custom wire mesh fabrication has become a significant area in the architectural design and industrial fabrication that includes the evolving wire mesh construction. For visual or practical purposes including safety and filtration wire mesh has been integrated into construction and industrial applications. One of the companies that are very active in this area is called Metart Building Tech. Being one of the wire mesh manufacturing elites, Metart Building Tech focuses on working on wire mesh fabrication for particular and diverse industries and buildings development.

The Features of Custom Wire Mesh Fabrication

Custom wire mesh fabrication includes the design and production or alteration of wire mesh structures detailing specific projects. This process often involves the choice of mesh material, the customising of the mesh pattern, and all other necessary activities that conform to the end-use of the product.

Metart Building Tech is a well established company with innovative modular wire mesh components built to the specifications of today’s architectural practices. The range of the company is extensive and includes custom facades, interior and industrial decorations. Due to their ability to merge five star looks with architecture, they are extremely popular with architects, designers and industrialists globally.

Material Versatility in Wire Mesh Fabrication

The as-built fabrication held great value but the material aspect was taken to another level due to the potential to work with a variety of materials. Metart Building Tech further expands its wire mesh offerings using different metals, each having specific benefits depending on the environment and application. The common materials are stainless steel, aluminum, copper, brass and bronze amongst others and these seek to strike a balance in strength, resistance to corrosive action and pleasing appearance.

For example, stainless steel is praised for its resistance to rust and durability which also explains why it is widely used in extreme conditions like the oil and gas industry. Well, due to the color and bactericidal properties of copper and brass, they find a lot of use in decoration. Using these materials, metart constructs wire mesh that performs even better than its intended purpose by beautifying building structures.

In addition, Metart works with special alloys like Inconel, Monel or nickel based superalloys that are suited to supercritical applications that include aerospace and chemical industries where high heat and corrosion resistance are required. Since they are able to make wire mesh out of such a vast variety of materials, it is possible for them to provide very specialized products for a wide range of applications.

Innovative Fabrication Solutions

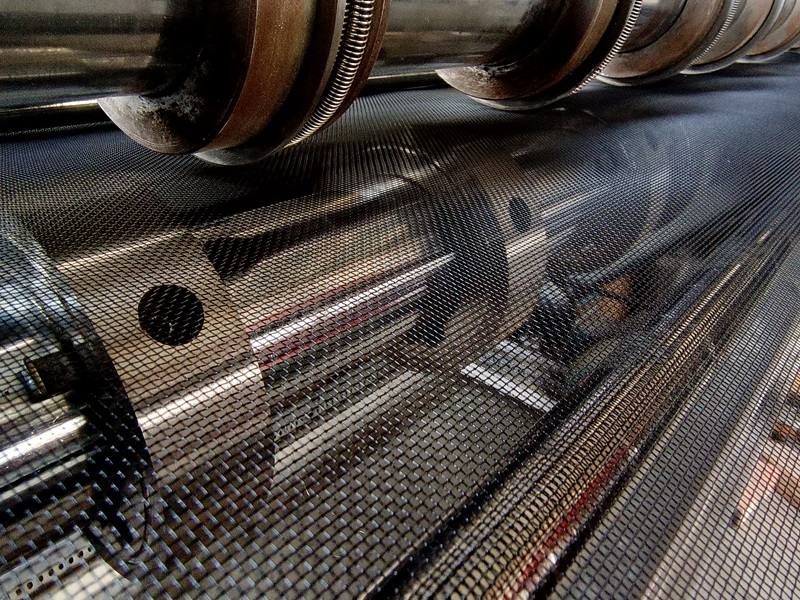

One of the biggest advantages of Metart Building Tech in terms of production of customized wire mesh is the use of innovative fabrication techniques. The company is well equipped with the appropriate technology in designing and manufacturing wire mesh products ranging from CNC punching, laser cutting to precision weaving to ensure that all wire mesh products are of the best and accepted standards.

Wire mesh can be created using different types of weaving methods which include plain weave, twill, and crimped pattern weaving. Such options make it possible for Metart to provide customized solutions according to the customer’s needs. For instance, pre crimped and lock crimped wire mesh have found applications in security and industrial filtration devices where there must be sufficient strength and durability of the product.

Similarly, Metart has provided woven wire mesh products for the façade applications for the purpose of adding mesh structural and even aesthetic enhancement to the buildings. They are usually employed in building’s outer walls, vertical enclosures, and even units within the building, having contemporary blacks and glazing systems and allowing natural ventilation and light with safety.

Customization for Architectural Applications

The fabricating of custom wire packaging meshes has countless benefits whereby most of the professionals enclosing architects and designers enjoy the luxury of good working tools resolvable for purpose enhancement. Metart Building Tech compliments its solutions with a wide range of customization to every particular project. Their wire mesh applications aimed at moistening residential, commercial and industrial buildings, favor the entire fabric of architecture rather than unsightly protruding out.

For example, the mesh is commonly used for facades, western design, as well as infills of mouth and hand rails, or in curtain wall systems. Such applications cause not only the aesthetic look of the edifices but also enhance the utility by providing wind flow, sun protection, and protection. Furthermore, wire mesh can also be incorporated in the interiors for furniture, in ceiling and wall decorations, as it is an effective light weight material for the modern use.

Metart has different sizes, patterns and finishes of the meshes hence the design has no limitation. Industrial patterns of wire mesh combines exquisite beauty and application ranging from eye catching patterned idea decorations covering the finer inner of structures to coarse heavy duty external patterns for industrial buildings.

Industrial Applications of Wire Mesh

While the architectural application of wire mesh is one of the major areas of the Metart Building Tech activity, the company also develops wire mesh for industrial usage. Such products are applied in many fields including but not limited to filtration, separation and reinforcement. Stainless steel wire mesh is quite popular for the fact that its usage boasts industrial facilities.

In liquid and gas filtration systems, wire mesh acts as a key element in assuring the reliability of the contaminants capture. Metart – sintered wire mesh consisting of several layers of woven wire mesh provides greater wear resistance and better filter performance. This stimulates such industries as petrochemicals, pharmaceuticals and wastewater treatment where filtration is critical in order to deliver quality product and maintain the integrity of the system.

Neither of the below portions explains today’s context and includes uses of the custom made wire mesh solutions provided by Metart in construction namely reinforcement of concrete, building fences and safety barriers. These industrial applications emphasize the usefulness and strength of wire mesh employed both as a means of function and protection.

Sustainability and Durability

These days within the construction and industrial field especially the tittle sustainability has been a hot issue. With wire mesh this is easy because it can be reused and lasted for a long time. Metart Building Tech guarantees that its products not only conform to required standards in the building industry but also advocates for practices that do not harm nature. Take stainless steel for instance it is 100% recyclable and thus most favorable in projects that seek to minimize the effects of construction on the environment.

Compared to other constructions, wire mesh also requires very little up-keep, thus increasing its durability. It is because of its capacity to withstand corrosion that even after many years, structures do not require frequent replacements hence remain aesthetically pleasing to the eye.

Why Select Metart Building Tech for Custom Wire Mesh Fabrication?

With Metart Building Tech, the company is a major player in wire mesh manufacture due to its quality enhancement, management system and care for customers. With a highly developed fully equipped and high-tech plants, the organization has the much required capability of providing wire mesh systems that will offer high precision and performance.

Also, Metart is fully aware of all the particulars of wire mesh including performance and appearance and is, therefore, ready to render the same services but to the satisfaction of the users. The company’s wire mesh products effortlessly apply to any purpose: industrial filtration, architectural, security, or any other, and, moreover, do it with a long-lasting quality.

In addition, Metart’s management staff has enough geographical coverage and project experience to perform tasks of any magnitude and of any complexity. Handles all types of projects from minor housing work to numerous engineering systems in major industries. The company is capable and able to address the most specific craziness.

Conclusion

Manufacturing custom wire mesh can be considered as one of the important aspects of present-day architecture and industrial design since it combines theater functionality, endurance and beauty. Metart Building Tec h equips modern industries with high-end wire mesh by virtue of its diversified capabilities in fabrication and materials and its penchant for being ahead within its sector.

Ideal for addressing the enhancements of the appearance of a structure, the efficiency of the systems of industrial filtration, or the toughness of security measures, custom wire mesh products from Metart are the appropriate tool. This makes them the preferred experts in the eyes of architects, designers, and engineers globally since they combine the precision of technological advancements and the art of handcrafting.