Metal testing is an essential procedure that protects the robustness, dependability, and durability of different supplies utilized in various industries. The need for materials resistant to corrosion has led to the establishing of a

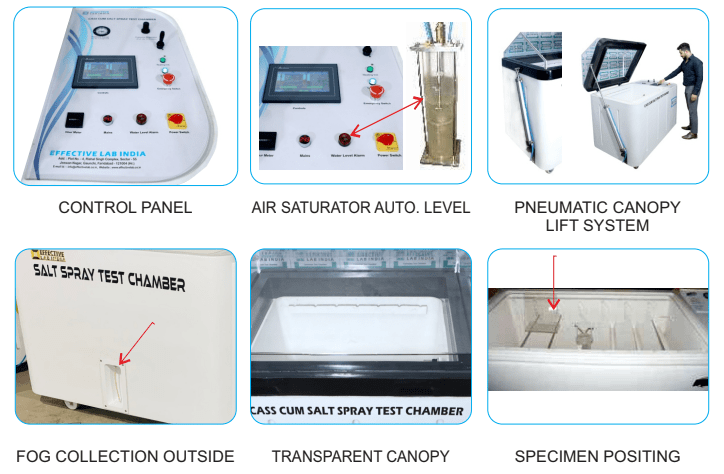

salt spray chamber as a crucial instrument for evaluating metal surfaces. Leading testing equipment manufacturer Effective Lab India provides a variety of innovative salt spray chambers to meet a range of metal testing requirements.

What is a Salt Spray Chamber?

A salt spray chamber, also known as a

salt fog test chamber, is a specialized piece of equipment used to test the corrosion resistance of metals and coated surfaces. It simulates harsh environmental conditions, like salt-laden atmospheres, to accelerate the corrosion process and assess how metals behave under such conditions.

Salt spray chamber procedureThe test specimens are continually coated with a fine mist, or “spray,” created by atomizing a salt solution in a controlled atmosphere created by the chamber. This configuration simulates the corrosive effects of salty surroundings, such coastlines and roads coated in De-icing salts. It is possible to modify the length and intensity of exposure to meet the unique needs of various exams.

Why Metal Testing is Essential

Corrosion ResistanceCorrosion can severely impact the structural integrity and functionality of metal products. By testing metals in a salt spray chamber, manufacturers can identify potential weaknesses and enhance corrosion resistance, ultimately extending the lifespan of their products.

Quality AssuranceMetal testing is a key aspect of quality assurance, ensuring that products meet the required standards and specifications. This is particularly important in industries where safety and reliability are critical, such as automotive, aerospace, and construction.

Industry ComplianceMany industries are governed by strict regulations that mandate specific testing procedures for metals. Salt spray testing helps companies comply with these standards, avoiding costly penalties and ensuring market access.

Key Test Methods for Metal Testing Using a Salt Spray Chamber

Neutral Salt Spray (NSS) TestOverviewThe Neutral Salt Spray (NSS) test is the most common method used to assess the corrosion resistance of metals and coatings. It involves exposing the test specimens to a neutral pH salt spray environment, typically using a 5% sodium chloride solution.

Procedure· Prepare the test specimens and ensure they are clean and free of contaminants.· Place the specimens in the

salt spray chamber at a specified angle.· Set the chamber to continuously spray the salt solution at a controlled temperature, usually around 35°C (95°F).· Monitor the specimens over a specified period, ranging from hours to weeks, depending on the test requirements.

ApplicationsThe NSS test is widely used in industries like automotive, marine, and construction to evaluate the corrosion resistance of metals, paints, and coatings.

Acetic Acid Salt Spray (AASS) Test

OverviewThe Acetic Acid Salt Spray (AASS) test is a variation of the NSS test, where acetic acid is added to the salt solution to lower the pH, creating a more aggressive testing environment.

Procedure· Mix acetic acid with the sodium chloride solution to achieve a pH of around 3.1.· Follow the same steps as the NSS test, with the chamber temperature set to 50°C (122°F).· Observe the specimens for signs of corrosion, such as rust or blistering.

ApplicationsThe AASS test is commonly used for testing metals with protective coatings, such as anodized aluminum, and is particularly relevant in industries where enhanced corrosion resistance is essential.

Copper-Accelerated Acetic Acid Salt Spray (CASS) Test

OverviewThe

Copper-Accelerated Acetic Acid Salt Spray (CASS) test is an even more aggressive method, incorporating copper chloride into the salt solution to further accelerate the corrosion process.

Procedure· Add copper chloride to the acetic acid and sodium chloride solution, creating a highly corrosive environment.· Expose the test specimens to this solution at a chamber temperature of 50°C (122°F).· Monitor the specimens for signs of rapid corrosion.

ApplicationsThe CASS test is particularly suited for evaluating the corrosion resistance of decorative coatings, such as those found on automotive parts and household fixtures.

Cyclic Corrosion Testing (CCT)

OverviewCyclic Corrosion Testing (CCT) involves exposing metal specimens to alternating periods of salt spray, humidity, and drying cycles. This method more accurately simulates real-world environmental conditions, making it a valuable tool for assessing long-term corrosion resistance.

Procedure· Program the chamber to cycle between salt spray, high humidity, and dry air conditions.· Expose the specimens to these cycles over a predetermined period.· Evaluate the corrosion patterns that develop over time.

ApplicationsCCT is widely used in the automotive and aerospace industries, where materials are exposed to varying environmental conditions.

Detailed Overview of NSS, AASS, and CASS Tests

Comparing the Different ApproachesDifferent degrees of corrosion severity are available for the NSS, AASS, and CASS tests, making them appropriate for a range of applications. Although NSS is the best option for general corrosion testing, more severe conditions that call for increased corrosion resistance are better suited for AASS and CASS.

Appropriate Metal Types for Every Technique

NSS: Appropriate for evaluating metals coated with zinc, aluminum, and steel.

AASS: Optimal for coated metals like galvanized steel and aluminum.

CASS: Perfect for pieces made of metal that have ornamental coatings, such chrome plating.

Elements Affecting Test Outcomes

Metal Content

The metal’s resistance to corrosion is mostly determined by its chemical makeup. For instance, in salt spray testing, stainless steel usually shows superior resistance over carbon steel.

Environmental Conditions

The test’s result may vary depending on the chamber’s temperature, humidity, and salt solution concentration. In these circumstances, consistency is essential to getting trustworthy outcomes.

Test Duration

The rusting gets worse the longer it is exposed to the salt spray. The planned use of the metal product should be taken into consideration when choosing the test period.

Applications of Salt Spray Testing in Various Industries

Automotive IndustrySalt spray testing is essential in the automotive industry to ensure the longevity and safety of vehicles exposed to road salts and harsh weather conditions.

Aerospace IndustryIn aerospace, where materials are subjected to extreme environmental conditions, salt spray testing helps in selecting metals that can withstand corrosion over extended periods.

Marine IndustryMarine environments are highly corrosive due to the presence of saltwater. Salt spray testing is crucial for ensuring the durability of metals used in ships, offshore platforms, and other marine structures.

Construction IndustrySalt spray testing is used in the construction industry to evaluate the corrosion resistance of metals used in building structures, bridges, and other infrastructure.

Advantages of Using a Salt Spray Chamber for Metal Testing

Accurate Simulation of Real-World ConditionsSalt spray chambers provide a controlled environment that accurately simulates the corrosive effects of real-world conditions, making it easier to predict how metals will perform in the field.

Cost-Effective TestingCompared to other testing methods, salt spray testing is relatively cost-effective, providing valuable data without the need for expensive field tests.

Rapid ResultsSalt spray testing accelerates the corrosion process, allowing manufacturers to obtain results quickly and make timely decisions regarding material selection and product design.

Effective Lab India’s Expertise in Salt Spray Chambers

Modern Salt Spray Chambers with the Newest Technology Available from Effective Lab India Provide exact control over testing parameters and precise outcomes.

Effective Lab India offers customization options to customize their salt spray chambers to individual specifications, acknowledging that various sectors have distinct testing requirements. Effective Lab India’s salt spray chambers are well-received by customers who attest to their dependability and efficiency. This underscores the company’s dedication to excellence and client contentment.

Choosing the Right Salt Spray Chamber for Your Needs

Key ConsiderationsWhen selecting a

salt spray test chamber, consider factors such as the size of the chamber, the type of metals you are testing, and the specific test methods you plan to use.

Recommendations from Effective Lab IndiaEffective Lab India offers expert guidance in choosing the right salt spray chamber, ensuring that you invest in equipment that meets your testing needs and delivers accurate results.

Conclusion

An essential technique for evaluating the corrosion resistance of metals and coatings is salt spray testing. Making educated judgments on material selection and product design will be aided by knowing the various test techniques and their applications, regardless of your industry: construction, automotive, aerospace, or maritime. The cutting-edge salt spray chambers from Effective Lab India provide the accuracy and dependability required for comprehensive metal testing.

Cyclic salt spray chambers are a major equipment used by the automotive, aerospace, and construction sectors for corrosion testing and material durability evaluation. You can assess and enhance your items more quickly the faster you can complete these tests without compromising accuracy. But how do you ensure your cyclic salt spray chamber operates efficiently? In this blog, we’ll explore practical strategies to optimise your testing process while maintaining high-quality results.

Cyclic salt spray chambers are a major equipment used by the automotive, aerospace, and construction sectors for corrosion testing and material durability evaluation. You can assess and enhance your items more quickly the faster you can complete these tests without compromising accuracy. But how do you ensure your cyclic salt spray chamber operates efficiently? In this blog, we’ll explore practical strategies to optimise your testing process while maintaining high-quality results.

Metal testing is an essential procedure that protects the robustness, dependability, and durability of different supplies utilized in various industries. The need for materials resistant to corrosion has led to the establishing of a

Metal testing is an essential procedure that protects the robustness, dependability, and durability of different supplies utilized in various industries. The need for materials resistant to corrosion has led to the establishing of a

Natural processes like corrosion may cause damage to metals and other materials, eventually resulting in their destruction. This is particularly challenging for sectors like construction, aircraft, and automotive where material integrity is essential. Corrosion testing is necessary for the prevention of material quality failures. Salt spray testing is a dependable and common approach among the many accessible procedures.

Natural processes like corrosion may cause damage to metals and other materials, eventually resulting in their destruction. This is particularly challenging for sectors like construction, aircraft, and automotive where material integrity is essential. Corrosion testing is necessary for the prevention of material quality failures. Salt spray testing is a dependable and common approach among the many accessible procedures.  Metal surfaces meet a recurring problem with corrosion in a variety of industries. Exposure to extreme weather conditions will severely damage the integrity of the metal. This metal can be used in everything from building materials to car parts. Effective Lab

Metal surfaces meet a recurring problem with corrosion in a variety of industries. Exposure to extreme weather conditions will severely damage the integrity of the metal. This metal can be used in everything from building materials to car parts. Effective Lab  Natural processes such as corrosion cause metal products to gradually lose strength, appearance, and functionality. Metals undergo chemical reactions that result in rust and other types of corrosion. These reactions occur when they are subjected to severe environmental factors including moisture, salt, and oxygen. This reduces the metal’s lifetime and jeopardises its structural integrity, necessitating expensive repairs or replacements. One effective way to combat this issue is through testing. The

Natural processes such as corrosion cause metal products to gradually lose strength, appearance, and functionality. Metals undergo chemical reactions that result in rust and other types of corrosion. These reactions occur when they are subjected to severe environmental factors including moisture, salt, and oxygen. This reduces the metal’s lifetime and jeopardises its structural integrity, necessitating expensive repairs or replacements. One effective way to combat this issue is through testing. The  A specialised testing machine used to simulate the effects of materials exposed to saltwater is called a

A specialised testing machine used to simulate the effects of materials exposed to saltwater is called a