In today’s world, where technology drives almost every aspect of our daily lives, the role of electrical systems cannot be overstated. From homes and offices to industrial facilities, electrical wiring forms the backbone of modern infrastructure. One critical yet often overlooked component that ensures the safe and efficient delivery of electricity is electrical cable ducts. These ducts play a pivotal role in protecting electrical cables and wires, contributing to both safety and longevity. In this guest blog post, we will explore the importance of electrical cable ducts, their types, applications, and why they should be a primary consideration in any electrical installation.

What Are Electrical Cable Ducts?

Electrical cable ducts, also known as cable trays or raceways, are protective conduits designed to house electrical cables and wires. These ducts are typically made of materials like metal (steel or aluminum), plastic, or fiberglass. Their primary function is to provide a safe, organized space for electrical cables, preventing damage from external factors such as moisture, chemicals, physical impacts, or environmental exposure.

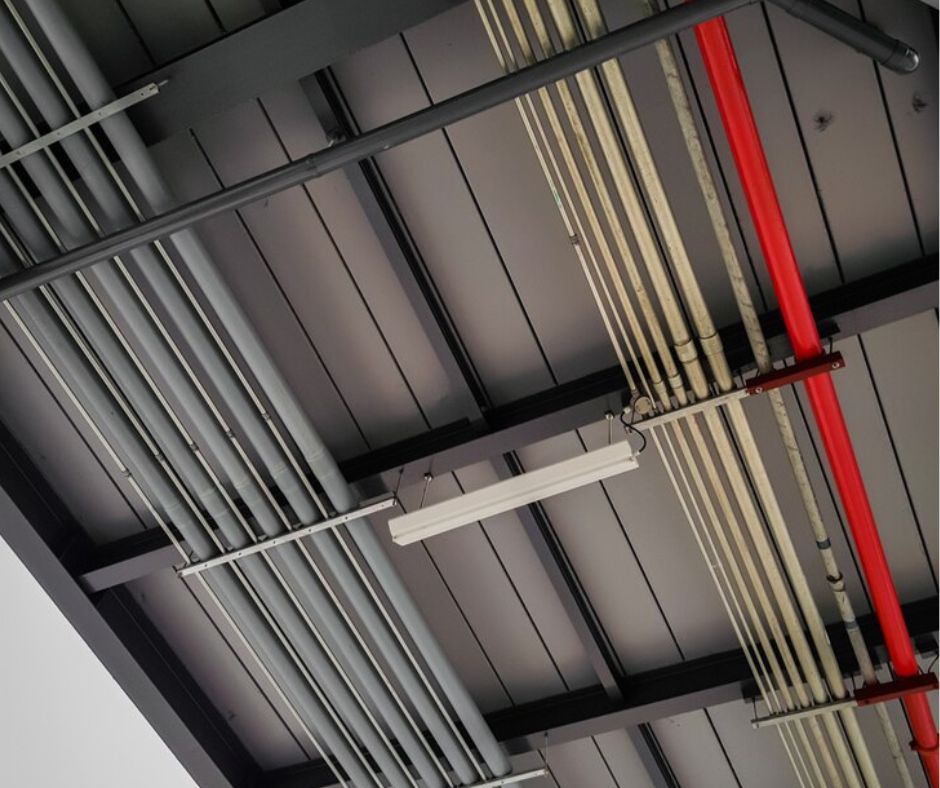

Cable ducts can be installed both indoors and outdoors, depending on the type of infrastructure and the nature of the electrical installation. They are essential for managing and organizing a large number of cables, especially in complex systems like those found in factories, office buildings, and other large-scale facilities.

Why Are Electrical Cable Ducts Important?

Electrical cable ducts are not merely for aesthetic purposes—they serve several key functions that improve the overall electrical system:

- Protection Against Physical Damage: Electrical cables are vulnerable to physical damage from external factors such as impact, pressure, or abrasion. Whether they are subjected to heavy machinery in industrial settings or foot traffic in office buildings, cables are susceptible to being damaged if not adequately protected. Electrical cable ducts provide a barrier against these hazards, reducing the risk of exposed or cut wires that could lead to short circuits, power outages, or electrical fires.

- Improved Safety: A well-organized cable management system within ducts helps minimize the risk of electrical accidents. Without proper organization, cables may get tangled or crossed, creating a fire hazard or increasing the likelihood of tripping accidents. Cable ducts prevent cables from coming into contact with each other, reducing the risk of sparks, heat generation, or electrical faults. Additionally, ducts reduce the likelihood of unauthorized access to live electrical wires, ensuring the safety of both workers and residents.

- Efficient Cable Management: Managing cables within a building or industrial site can be a complex task, especially when you have a large number of circuits to organize. Without proper cable ducts, wires may become disorganized and harder to trace or maintain. Electrical cable ducts provide a clear path for cables, which makes it easier to troubleshoot problems, make modifications, or add new wiring without disturbing the existing setup.

- Environmental Protection: Electrical cables exposed to environmental elements, such as moisture, temperature fluctuations, or corrosive chemicals, are at risk of deteriorating prematurely. Cable ducts shield electrical cables from these elements, extending their lifespan and ensuring their reliable performance over time. For outdoor installations, weather-resistant ducts are available to protect cables from harsh weather conditions, while indoor ducts can protect cables from humidity and accidental spills.

- Ease of Installation and Maintenance: Installing electrical systems without proper cable management can be a time-consuming and expensive process. With electrical cable ducts, wiring installations are more streamlined and organized. The ducts create a neat and accessible space for cables, allowing for quicker installation and facilitating easier upgrades or repairs when necessary. Maintenance workers can quickly identify and fix problems within ducts without needing to tear down walls or floors to access cables.

Types of Electrical Cable Ducts

There are various types of electrical cable ducts, each designed to meet different needs and requirements. Below are the most common types:

- Metal Cable Ducts: Metal cable ducts are widely used in industrial settings due to their strength, durability, and ability to withstand harsh environments. Steel and aluminum are the most common materials used to make metal ducts, as they offer excellent protection against physical damage and environmental factors. Metal cable ducts are ideal for areas with high traffic or machinery that may put pressure on the cables.

- Plastic Cable Ducts: Plastic cable ducts are lighter and more affordable than their metal counterparts. They are often used in commercial and residential settings, as they are easy to install and offer reliable protection for electrical cables. Plastic ducts are also resistant to corrosion, making them a popular choice for environments where moisture is a concern. PVC (polyvinyl chloride) is one of the most commonly used materials for plastic ducts due to its strength and ease of installation.

- Flexible Cable Ducts: Flexible cable ducts are designed for applications where rigid ducts may not be suitable. These ducts are made from flexible materials such as rubber, plastic, or fabric, allowing them to bend and conform to various shapes. Flexible ducts are commonly used in tight or irregular spaces where fixed ducts would be difficult to install. They are often used for temporary installations or areas that require frequent cable adjustments.

- Open Cable Trays: Open cable trays are a type of cable duct that provides a wide, open channel for cables. They are often used in larger industrial or commercial buildings where there is a need for a large number of cables to be managed. Open cable trays are easy to install and offer good airflow, which helps prevent overheating of cables. However, they are less protective than fully enclosed ducts and may not be suitable for environments where physical protection is a priority.

- Raceways: Raceways are a type of enclosed cable duct used to protect electrical cables from dust, dirt, and physical damage. Raceways are often installed in walls or ceilings, providing a neat, hidden pathway for cables. They are typically used in commercial and residential buildings where aesthetic considerations are important, and cables need to be hidden from view.

Applications of Electrical Cable Ducts

Electrical cable ducts are used in a wide range of industries and environments. Some of the most common applications include:

- Industrial Facilities: In factories, manufacturing plants, and warehouses, electrical cable ducts are essential for protecting and managing the numerous cables that power machinery, lighting, and other equipment. Metal cable ducts are often preferred in these environments due to their robust nature and ability to withstand the stresses of industrial operations.

- Commercial Buildings: In office buildings, retail stores, and shopping malls, electrical cable ducts are used to organize and protect the electrical cables that provide power to lighting, computers, HVAC systems, and more. Both metal and plastic ducts are common in these environments, depending on the specific needs of the building.

- Residential Homes: Electrical cable ducts are also used in residential homes to conceal and protect electrical wiring in walls, ceilings, and floors. This helps keep the wiring system organized and reduces the risk of damage or electrical accidents. PVC ducts are commonly used in these applications due to their affordability and ease of installation.

- Outdoor Installations: Electrical cable ducts are often used in outdoor environments to protect cables exposed to weather elements. Whether it’s a streetlight system, outdoor signage, or an irrigation system, outdoor cable ducts ensure that electrical wiring remains safe and operational, even in harsh weather conditions.

Conclusion

Electrical cable ducts may not always be visible or glamorous, but they are an essential part of modern infrastructure. By offering protection, organization, and safety, these ducts contribute significantly to the reliability and longevity of electrical systems. Whether in an industrial plant, commercial building, or residential home, investing in high-quality cable ducts is a crucial step in ensuring the smooth operation of electrical systems and the safety of individuals working with or around them.

When selecting the right type of electrical cable duct, it is important to consider factors such as material, environment, and the type of installation required. Whether you’re looking for a solution for a small-scale project or a large industrial installation, there is a cable duct solution available to meet your needs.

If you’re looking for high-quality electrical cable ducts, Tejara Direct offers a range of products to ensure your electrical wiring is well protected and managed. With expert guidance and reliable products, you can ensure the longevity and safety of your electrical systems for years to come.