Introduction

Ethyl acetate is a widely used organic solvent with applications in industries ranging from coatings and adhesives to pharmaceuticals and food processing. Its pleasant, fruity odor and effective solvency make it a popular choice for a variety of uses. As the demand for ethyl acetate continues to grow, establishing a manufacturing plant presents a significant business opportunity. The Ethyl Acetate Manufacturing Plant Project Report offers a comprehensive guide for entrepreneurs and investors interested in setting up a production facility, covering market analysis, infrastructure requirements, raw materials, manufacturing processes, and financial projections.

Market Analysis

Understanding Demand

Ethyl acetate is valued for its:

- Solvent Properties: It is used in paints, coatings, and adhesives for its ability to dissolve various substances and evaporate quickly.

- Pharmaceuticals: Employed as a solvent in the synthesis of drugs and in extraction processes.

- Food and Beverages: Used as a flavoring agent and in food processing due to its fruity aroma.

- Cleaning Products: Included in formulations for its effective solvent properties.

Trends and Opportunities

- Growing Industrial Applications: Increased use in automotive, construction, and consumer goods industries drives demand.

- Regulatory Changes: Stricter environmental regulations are pushing the industry toward greener production technologies, creating opportunities for innovation.

- Emerging Markets: Developing regions are expanding industrial activities, increasing the demand for solvents like ethyl acetate.

Get a Free Sample Report with Table of Contents @

Competitive Landscape

The ethyl acetate market is competitive, with several global and regional players. Key factors for success include product quality, cost efficiency, technological advancements, and strategic marketing. Analyzing competitors’ strengths and weaknesses can provide insights into market opportunities and help refine business strategies.

Plant Location and Infrastructure

Choosing the Right Location

Selecting an optimal location for an ethyl acetate manufacturing plant involves several considerations:

- Proximity to Raw Materials: Being close to sources of ethanol and acetic acid can reduce transportation costs and ensure a steady supply.

- Accessibility: The location should be well-connected to transportation networks for efficient distribution of raw materials and finished products.

- Regulatory Environment: Ensure the location complies with local regulations regarding manufacturing practices, environmental standards, and safety requirements.

Infrastructure Requirements

- Production Facility: The plant should be equipped with machinery and infrastructure for the production of ethyl acetate. Essential equipment includes:

- Reactors: For the esterification reaction between ethanol and acetic acid.

- Distillation Columns: To separate and purify ethyl acetate from other byproducts.

- Storage Tanks: For storing raw materials and finished products.

- Cooling Systems: To manage heat generated during the reaction and maintain optimal operating conditions.

- Storage: Adequate storage facilities are necessary for raw materials and finished products. Proper conditions must be maintained to prevent contamination and ensure product quality.

- Quality Control Laboratory: A laboratory for testing ethyl acetate quality, including purity, concentration, and other chemical properties, is essential for maintaining high standards.

Raw Materials and Suppliers

Key Raw Materials

- Ethanol: The primary feedstock for producing ethyl acetate. It is typically derived from agricultural sources.

- Acetic Acid: The second key ingredient in the esterification process, sourced from industrial production.

- Catalysts and Solvents: Used in the production process to enhance reaction efficiency and product quality.

Supplier Relationships

Building strong relationships with reliable suppliers ensures a consistent supply of high-quality raw materials. Establish contracts with multiple suppliers to mitigate risks related to supply chain disruptions and price fluctuations.

Manufacturing Process

The production of ethyl acetate involves several key steps:

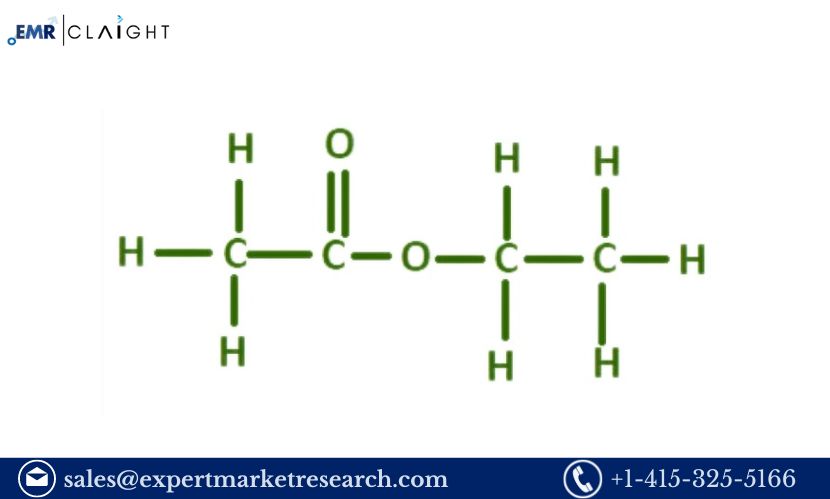

- Raw Material Preparation: Ethanol and acetic acid are prepared and mixed with catalysts for the esterification reaction.

- Esterification Reaction: The ethanol and acetic acid are reacted in a reactor under controlled conditions to produce ethyl acetate and water. This reaction typically requires an acid catalyst to proceed efficiently.

- Separation and Purification: The reaction mixture is distilled in columns to separate ethyl acetate from water and other byproducts. The resulting ethyl acetate is further purified to meet quality standards.

- Cooling and Storage: The purified ethyl acetate is cooled and transferred to storage tanks. Proper storage conditions are essential to maintain product quality.

- Quality Control: Throughout the production process, samples are tested to ensure the ethyl acetate meets purity, concentration, and other chemical property standards.

Financial Projections

Initial Investment

Setting up an ethyl acetate manufacturing plant requires significant initial investment. Key expenditures include:

- Machinery and Equipment: Costs for reactors, distillation columns, storage tanks, and cooling systems.

- Facility Construction: Building or leasing a production facility and installing necessary infrastructure.

- Raw Materials: Initial purchase of ethanol, acetic acid, and other materials required for production.

Operational Costs

Regular operational expenses include:

- Labor: Wages for production staff, quality control personnel, and administrative employees.

- Raw Materials: Ongoing costs for ethanol, acetic acid, and other materials.

- Utilities: Costs for electricity, water, and other utilities required for manufacturing.

Revenue Projections

Revenue will depend on factors such as production capacity, market demand, and pricing strategy. Conducting a detailed market analysis can help set competitive pricing and estimate potential revenue based on expected sales volumes.

Profit Margins

Analyzing profit margins involves considering production costs, raw material expenses, and market prices. Efficient production processes and cost management are crucial for achieving profitable margins.

Risk Management

Identifying Risks

- Raw Material Costs: Fluctuations in the prices of ethanol and acetic acid can impact production costs. Establish contracts with suppliers to manage this risk.

- Regulatory Compliance: Stay updated on regulations related to environmental standards, safety, and product quality.

- Market Demand: Changes in consumer preferences or economic conditions can affect demand. Regularly review market trends and adjust strategies as needed.

Mitigation Strategies

- Diversify Suppliers: Work with multiple suppliers to reduce dependency on a single source.

- Maintain Quality Standards: Implement rigorous quality control measures to ensure product consistency and compliance with industry standards.

- Monitor Market Trends: Stay informed about industry trends and consumer preferences to adapt your business strategy and meet changing demands.

FAQ

What is ethyl acetate and what are its primary uses?

Ethyl acetate is an organic solvent used in a variety of applications, including paints, coatings, adhesives, pharmaceuticals, and food processing.

What are the main steps in the ethyl acetate manufacturing process?

The main steps include raw material preparation, esterification reaction, separation and purification, cooling and storage, and quality control.

How much initial investment is required to set up an ethyl acetate manufacturing plant?

Initial investment varies based on plant size and location but typically includes costs for machinery, facility construction, and raw materials.

What factors should be considered when choosing a location for the plant?

Consider proximity to raw material suppliers, access to transportation networks, and compliance with local regulations related to manufacturing and environmental standards.

How can I ensure the quality of ethyl acetate products?

Implement strict quality control measures throughout the production process, including testing for purity, concentration, and other chemical properties. Use high-quality raw materials and maintain controlled manufacturing conditions.

What are the major risks in ethyl acetate manufacturing and how can they be managed?

Major risks include fluctuations in raw material prices, regulatory changes, and shifts in market demand. Manage these risks by diversifying suppliers, staying updated on regulations, and monitoring market trends.

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au/