Introduction

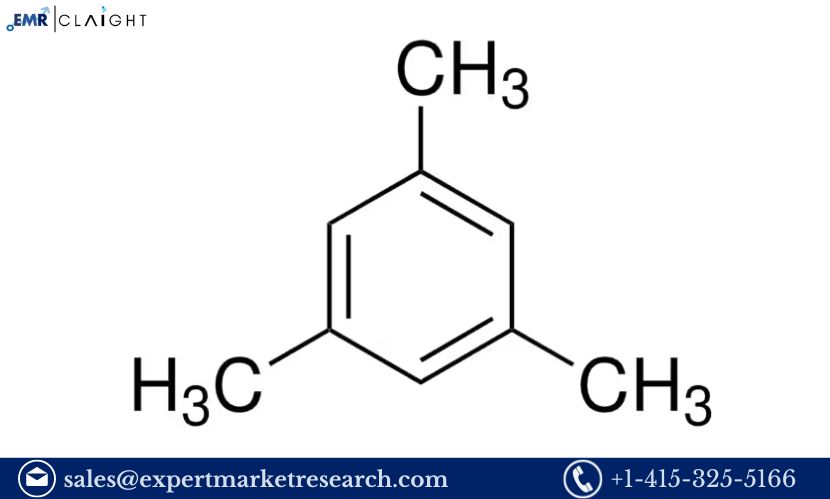

Mesitylene, also known as 1,3,5-trimethylbenzene, is a valuable aromatic hydrocarbon used in various industrial applications, including as a solvent, in chemical synthesis, and as a component in high-performance coatings. The Mesitylene Manufacturing Plant Project Report outlines the essential steps for setting up a plant dedicated to the production of mesitylene. This report provides a detailed overview of the project, including market analysis, project planning, production processes, and quality control measures, to guide stakeholders in establishing a successful and efficient mesitylene manufacturing facility.

Project Overview

Purpose and Objectives

The primary goal of the Mesitylene Manufacturing Plant Project is to develop a facility capable of producing high-quality mesitylene efficiently. Key objectives include:

- Reliable Production: Implementing an efficient production process to ensure a consistent supply of mesitylene.

- Quality Assurance: Ensuring the produced mesitylene meets industry standards for purity and performance.

- Market Expansion: Capturing a significant share of the mesitylene market by optimizing production and distribution strategies.

Get a Free Sample Report with Table of Contents @

Market Analysis

A thorough market analysis is crucial for understanding the potential success of the manufacturing plant. This analysis includes:

- Demand Assessment: Evaluating current and future demand for mesitylene in various industries, such as chemicals, coatings, and solvents.

- Competitive Landscape: Identifying existing manufacturers and their market share to develop competitive strategies and identify opportunities.

- Application Trends: Understanding trends in mesitylene applications to align production capabilities with market needs.

Project Planning

Site Selection

Selecting the right location for the manufacturing plant is critical for its success. Key considerations include:

- Raw Material Access: Proximity to suppliers of key raw materials and feedstocks used in mesitylene production, such as benzene and methylating agents.

- Infrastructure: Availability of essential infrastructure, including utilities (water, electricity), transportation links, and storage facilities.

- Regulatory Compliance: Ensuring the site complies with local zoning laws, environmental regulations, and industry standards.

Regulatory Compliance

Compliance with regulatory requirements is essential for operating the plant legally and safely. Key aspects include:

- Licensing and Permits: Obtaining the necessary licenses and permits from relevant authorities to operate the manufacturing facility.

- Safety Standards: Adhering to safety regulations related to the handling of hazardous materials and ensuring worker safety.

- Environmental Regulations: Complying with environmental regulations regarding emissions, waste management, and overall environmental impact.

Technology and Equipment

The production of mesitylene requires specialized technology and equipment. Key components include:

- Reactor Systems: For the chemical reaction to produce mesitylene from benzene and methylating agents.

- Distillation Columns: To separate and purify mesitylene from other by-products and unreacted materials.

- Storage Tanks: For storing raw materials and finished mesitylene.

- Packaging Machinery: For packaging mesitylene in suitable containers for distribution.

Manufacturing Process

Raw Materials

The primary raw materials for producing mesitylene are:

- Benzene: The base compound used in the production of mesitylene.

- Methylating Agents: Such as methyl chloride or methanol, which are used to introduce methyl groups to the benzene molecule.

Ensuring the quality and consistency of these raw materials is crucial for maintaining high production standards.

Production Steps

- Preparation: Raw materials, including benzene and methylating agents, are prepared and measured according to the required formulations.

- Reaction: The prepared raw materials are introduced into a reactor system under controlled conditions to initiate the chemical reaction that produces mesitylene.

- Separation: The reaction mixture is processed using distillation columns to separate mesitylene from other by-products and unreacted materials.

- Purification: Mesitylene is further purified to achieve the desired level of purity and remove any impurities.

- Storage: The purified mesitylene is stored in suitable tanks until it is ready for packaging.

- Packaging: The mesitylene is packaged in secure containers to ensure stability and prevent contamination during storage and transportation.

Quality Control

Maintaining high-quality standards is essential in mesitylene production. The quality control process includes:

- Raw Material Testing: Verifying the quality and suitability of incoming raw materials before use in production.

- In-Process Monitoring: Monitoring production parameters such as temperature, pressure, and reaction time to ensure consistency and quality.

- Final Product Testing: Conducting thorough tests on the finished mesitylene to confirm its purity, composition, and compliance with industry standards.

Environmental and Safety Considerations

Environmental Impact

The production of mesitylene can have environmental implications. Addressing these impacts involves:

- Waste Management: Implementing systems for the safe disposal and treatment of chemical waste generated during production.

- Emission Control: Using technologies and practices to minimize emissions and comply with environmental regulations.

Safety Measures

Worker safety is a top priority in the manufacturing plant. Key safety measures include:

- Personal Protective Equipment (PPE): Providing appropriate PPE to all workers involved in handling raw materials and operating machinery.

- Training: Regularly training employees on safety protocols, proper handling of hazardous materials, and emergency response procedures.

- Safety Equipment: Installing safety features such as emergency showers, eyewash stations, and fire extinguishers.

Financial Analysis

Cost Estimation

Accurate cost estimation is crucial for financial planning. Key cost components include:

- Capital Investment: Costs related to plant construction, equipment purchase, and installation.

- Operational Costs: Ongoing expenses such as raw materials, labor, utilities, and maintenance.

- Marketing and Distribution: Costs associated with promoting and distributing mesitylene.

Profitability Analysis

Conducting a profitability analysis helps assess the project’s financial viability. This includes:

- Revenue Forecasting: Estimating potential revenue based on market demand, pricing strategies, and sales channels.

- Return on Investment (ROI): Calculating the ROI to evaluate the financial benefits and sustainability of the project.

FAQ

What is mesitylene used for?

Mesitylene is used in various applications, including as a solvent in chemical processes, a component in high-performance coatings, and a precursor in the synthesis of other chemicals. It is valued for its stability and chemical properties.

What are the main challenges in manufacturing mesitylene?

Key challenges include managing the chemical reaction to ensure high yield and purity, handling and storing hazardous materials, and adhering to environmental and safety regulations.

How long does it take to set up a mesitylene manufacturing plant?

Setting up a mesitylene manufacturing plant typically takes between 12 to 24 months, depending on factors such as site preparation, equipment installation, and regulatory approvals.

What safety measures are required for handling mesitylene?

Safety measures include using personal protective equipment (PPE) such as gloves and goggles, providing regular training on safety protocols, and implementing strict procedures for handling and storing hazardous materials.

How can I ensure environmental compliance in the production of mesitylene?

Ensuring environmental compliance involves implementing effective waste management systems, controlling emissions, and adhering to local and international environmental regulations. Regular environmental audits and impact assessments can help maintain compliance and minimize environmental impact.

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au/