Introduction

An Amino Acid Manufacturing Plant Project Report is a comprehensive document that outlines the process, infrastructure, and market potential involved in setting up a facility for the production of amino acids. Amino acids are organic compounds that play a crucial role in various biological functions, such as protein synthesis, enzyme production, and neurotransmission. They are essential for human and animal health and have widespread applications across industries like pharmaceuticals, food, agriculture, and biotechnology.

This project report provides insights into the steps involved in setting up an amino acid manufacturing plant, from raw material procurement to the final packaging of products. It serves as a valuable resource for entrepreneurs, investors, and businesses looking to enter the amino acid production market.

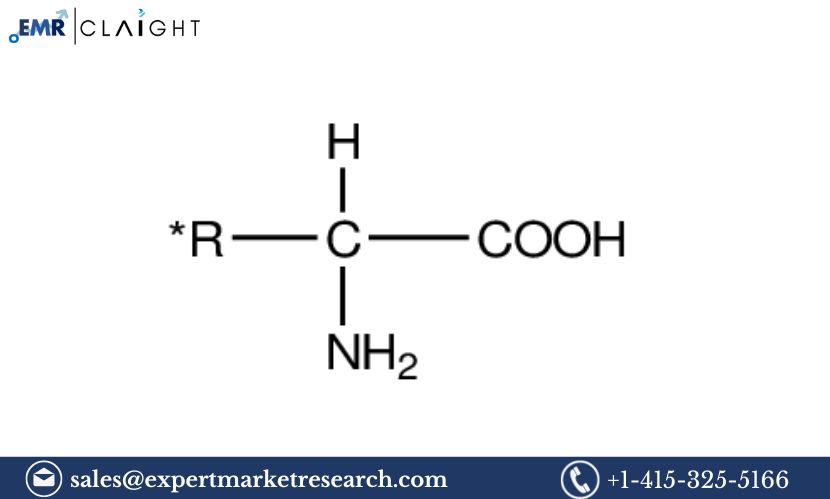

What Are Amino Acids?

Amino acids are the building blocks of proteins and are vital for various physiological functions. There are 20 standard amino acids, which can be divided into two categories:

- Essential Amino Acids: These cannot be synthesized by the human body and must be obtained through the diet. Examples include leucine, lysine, and tryptophan.

- Non-Essential Amino Acids: These can be synthesized by the body from other compounds. Examples include alanine, glutamine, and glycine.

Amino acids are used in multiple sectors, including:

- Pharmaceuticals: Amino acids are essential in the production of medicinal products, particularly in intravenous nutrition, and for the synthesis of peptides and proteins.

- Food & Beverages: Amino acids are used as flavor enhancers, nutritional supplements, and in the production of protein-based food products.

- Animal Feed: Amino acids are used in animal feed to promote healthy growth, improve feed efficiency, and ensure the nutritional needs of livestock.

- Cosmetics: Amino acids are used in skin care products for their moisturizing and conditioning properties.

Get a Free Sample Report with Table of Contents@

Raw Materials for Amino Acid Production

The production of amino acids involves both natural and synthetic sources, and the raw materials used can vary depending on the specific amino acid being manufactured. Common raw materials include:

- Carbon Source: Organic raw materials such as glucose, starch, and molasses are commonly used as carbon sources. These raw materials are converted into amino acids during the fermentation process.

- Nitrogen Source: Ammonium salts, urea, or nitrate are used to provide nitrogen, an essential element for amino acid synthesis.

- Minerals and Trace Elements: A variety of minerals, such as phosphates, sulfur, and calcium, are required to support the fermentation process and promote optimal microbial growth.

- Microorganisms: Microbial fermentation is the most common method for producing amino acids. Specific strains of bacteria, fungi, or yeasts are used to produce targeted amino acids through fermentation processes. For example, Corynebacterium glutamicum is commonly used to produce glutamic acid.

- Solvents and Chemicals: In some cases, chemicals like hydrochloric acid, sodium hydroxide, or other solvents may be used to purify amino acids or adjust pH levels during production.

Amino Acid Production Process

The production of amino acids generally involves two main processes: fermentation and chemical synthesis. The specific process used depends on the type of amino acid being produced and its intended application. The following is an outline of the general process:

1. Microbial Fermentation Process

Fermentation is the most commonly used method for manufacturing amino acids, particularly for essential amino acids. The steps involved are:

- Inoculum Preparation: A selected strain of microorganism (typically bacteria or yeast) is cultured in a medium containing the necessary nutrients (carbon, nitrogen, minerals) to promote growth.

- Fermentation: The inoculum is transferred into large fermentation tanks, where conditions such as temperature, pH, and oxygen levels are carefully controlled to optimize microbial growth and amino acid production. During fermentation, the microorganisms convert the raw materials (carbon and nitrogen sources) into amino acids.

- Harvesting: After the fermentation process is complete, the broth is filtered to remove the microorganisms and other solids. The amino acids are then isolated from the broth through techniques such as precipitation or solvent extraction.

- Purification: The isolated amino acids undergo purification processes such as crystallization, filtration, or chromatography to ensure they meet the required purity standards.

- Drying and Packaging: The purified amino acids are dried to remove excess moisture and are then packaged into suitable containers for shipment. Some amino acids may be converted into powders, while others may be formulated into tablets, capsules, or liquid forms.

2. Chemical Synthesis

For some amino acids, particularly non-essential amino acids, chemical synthesis may be used. This process involves the chemical reaction of starting materials (such as α-keto acids or derivatives) to produce the desired amino acid. Chemical synthesis typically requires highly controlled conditions and the use of catalysts to achieve optimal yields.

3. Enzymatic Process

In some cases, enzymes are used to catalyze the production of amino acids. This method is often used for the production of amino acids like glutamine, alanine, and serine, where specific enzymes are added to facilitate the conversion of raw materials into the target amino acid.

Plant Design and Infrastructure

Setting up an amino acid manufacturing plant requires significant investment in specialized infrastructure to ensure efficient production, quality control, and safety. Key aspects of plant design include:

- Raw Material Storage

The raw materials such as glucose, ammonium salts, and other nutrients need to be stored in dedicated areas. These storage facilities must be climate-controlled to ensure the stability of the materials. - Fermentation Tanks

Fermentation tanks are at the heart of the production process. These tanks must be equipped with temperature and pH control systems, as well as aeration systems to supply oxygen to the microorganisms during fermentation. - Purification and Extraction Equipment

After fermentation, the broth containing amino acids must be processed to isolate and purify the target amino acids. This involves the use of filtration, crystallization, and other separation technologies. - Quality Control Laboratory

A well-equipped quality control (QC) lab is essential for ensuring the final product meets the required specifications. The QC lab should be equipped with analytical instruments such as high-performance liquid chromatography (HPLC) and gas chromatography (GC) for amino acid analysis. - Drying and Packaging Area

Once the amino acids have been purified, they need to be dried to remove excess moisture. This is typically done in spray dryers or fluidized bed dryers. The dried product is then packaged for distribution. - Waste Management and Environmental Control

Amino acid manufacturing can generate waste by-products, so the plant must have a system for managing waste and complying with environmental regulations. This includes effluent treatment plants (ETPs) to neutralize harmful chemicals and ensure the safe disposal of waste.

Market Demand and Applications

The demand for amino acids is growing rapidly, driven by their applications across various industries. Key markets include:

- Pharmaceuticals

Amino acids are used in the pharmaceutical industry for the production of intravenous (IV) solutions, as well as in the synthesis of peptides and therapeutic proteins. - Animal Feed

Amino acids, particularly lysine, methionine, and threonine, are added to animal feed to improve the growth and health of livestock, poultry, and fish. - Food and Beverages

Amino acids are used as flavor enhancers, nutritional supplements, and protein fortifiers in food and beverages. They are commonly found in protein powders, health drinks, and infant formula. - Cosmetics

Amino acids are used in the cosmetic industry for their moisturizing, anti-aging, and conditioning properties. They are found in a wide range of skin care, hair care, and personal care products. - Biotechnology

Amino acids play a critical role in biotechnology applications, including enzyme production, cell culture media, and fermentation processes.

FAQs

1. What are amino acids used for?

Amino acids are used in pharmaceuticals, food and beverages, animal feed, cosmetics, and biotechnology. They are essential for protein synthesis and metabolic processes.

2. How are amino acids produced?

Amino acids are primarily produced through microbial fermentation, chemical synthesis, or enzymatic processes, depending on the type of amino acid.

3. What raw materials are required to produce amino acids?

The main raw materials include carbon sources (like glucose), nitrogen sources (such as ammonium salts), and microorganisms for fermentation.

4. How is quality controlled in amino acid production?

Quality control involves testing for purity, potency, and compliance with regulatory standards. Analytical techniques like HPLC and GC are used for amino acid analysis.

5. What industries use amino acids?

Amino acids are used in the pharmaceutical, food, animal feed, cosmetics, and biotechnology industries.

Related Reports

https://www.expertmarketresearch.com.au/reports/australia-hair-oil-market

https://www.expertmarketresearch.com.au/reports/australia-home-shopping-market

https://www.expertmarketresearch.com.au/reports/australia-hvac-market

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au